THAI SILK – WOVEN INTO THE FABRIC OF A CULTURE

Legendary origins

Legend has it that sometime around 3,000 B.C. the Empress Xi Lingshi was seated under a mulberry tree when a silkworm cocoon dropped into her steaming cup of tea and began to unravel. This accidental discovery led to the creation of silk weaving in China through her efforts and the empress is today the object of worship, known by the title of ‘Silkworm Mother’.

Ancient pottery from Ban Chiang

History

Charming as the tale is, the earliest silk known was found in tombs of a Neolithic site in Jiahu, Henan Province, and silk from around 3,630 B.C. was used to wrap a child’s corpse at a burial site in Xingyang, also in Henan Province. In Thailand, at the prehistoric site of Ban Chiang in the northeast of the country, there is evidence that silk was produced that might even predate Chinese production.

Bombyx mori, the silkmoth that makes it all possible

Silkmoths

Silk farmers in Thailand today cultivate two types of domesticated silkworms, the vast majority of which are from the Bombyx mori, the silkworm moth, the other being from the Samia ricini, known as the eri silkworm, which produces matte eri silk. Bombyx mori larvae produce the far better known glossy silk.

Silkworm food, mulberry leaves

Thailand’s silk industry

Thailand’s silk industry is mainly located in the northeast where the soil is particularly suitable for growing mulberry bushes, the leaves of which are fed to the silkworms, and is still produced using traditional methods that have changed little through the ages. The Centre for Excellence in Silk at Kamphaeng Saen campus of Kasetsart University’s is Thailand’s leading research facility in sericulture, silk farming and offers farmers technical assistance and also provides silkworm eggs.

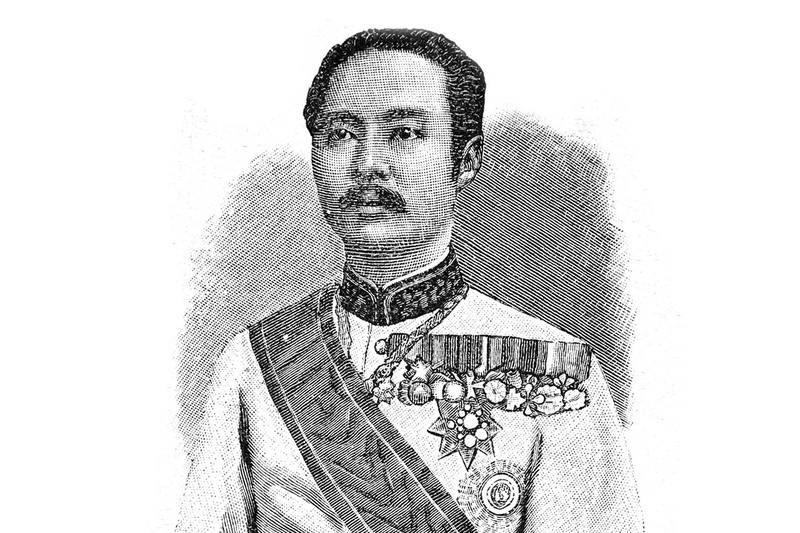

The very elegant King Chulalongkorn, an early promoter of Thai silk

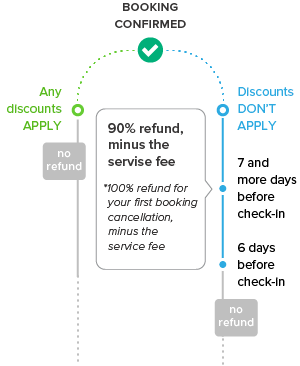

Creating a market

Oddly enough, Thai silk was not popular with Thai royalty, whose preference for Chinese silk meant that the locally produced silk’s main market was confined to a limited domestic trade. In the 1860s King Rama V, Chulalongkorn, took an interest and established a silk production enterprise near to Bangkok and encouraged its development but achieved limited results. Several other attempts were made throughout the early 20thcentury to establish the Thai silk industry, all which met with little success.

Jim Thompson creates a brand

In 1948 Jim Thompson and George Barrie started the Thai Silk Company primarily to sell to the foreign market and the US in particular. Although most of the designs Thompson produced bore little resemblance to what had been previously seen in Thailand, Thompson used his network of connections in New York to market his fabric as authentically Thai and in doing so created his brand. The company received a big fillip when in 1951 Irene Sharaff, the five-time Academy award winning costume designer, used Thai silk in her designs for the Rodgers and Hammerstein musical The King and Iafter which the company’s fortunes rose dramatically.

Jim Thompson Museum in Bangkok

Royal support

While Jim Thompson was capturing the international market, Queen Sirikit, the queen consort of King Bhumibol Adulyadej, made strenuous efforts to foster a domestic demand for Thai silk. She believed Thai silk to be a cultural treasure and encouraged silk weavers and sericulturists to improve both quality and production methods as a means of bolstering local economies in the poorest parts of the kingdom.

Silkworms feasting on mulberry leaves

From eggs to worms

The production of silk using traditional methods is a fairly laborious process and begins when the female silkmoth spends her very short four-day lifespan mating and then laying her eggs, usually about 300-500. The eggs are kept at about 25-29 degrees Celsius and hatch after about ten days from which the silkworms emerge. The silkworms are then placed in wicker baskets with fresh mulberry leaves for them to begin feeding on. They are fed four or more times a day and remain in the wicker baskets for another 20 to 30 days, increasing in weight about 10,000 times.

White silkworm cocoons

From worms to cocoons

At this stage, when their growth cycle is complete, the silkworms are ready to spin their cocoons and they are moved to a mountage (sometimes called a cocoonage), most commonly made of wood, bamboo, cardboard, twigs and even plastic, which offers a comfortable, secure place where the silkworms have just enough space to attach themselves and spin their cocoons. It takes on average about 3 days for the silkworm to complete its cocoon from a single fibre secreted from the mouth at a rate of about 4 and half inches (12 centimetres) a minute.

Boiling the cocoons to kill the silkworm pupae

Cocoon to thread

Roughly ten days after the silkworm has constructed its cocoon it has to be reeled before the pupae inside metamorphasizes into a moth and makes a hole from which it will escape and in the process destroy the continuous silk filament. The pupae inside are killed by boiling or steaming and retrieved from the cocoon as the silk thread is reeled. The pupae are then cooked, dehydrated and salted to make a snack that Thais love to eat with beer. They are also used to make animal feed, fertilizer and in the cosmetics industry.

Reeling in the threads

Once the filaments have been separated from the sericin, the gummy substance that holds them together, the silk filaments, usually from 6 to 20, are twisted together to form a larger single thread, about the thickness of a human hair, which is then reeled onto a spool. One single filament alone is not strong enough to be used as thread. The cocoons outer layer is coarser and used mainly in making fabric used in the furniture trade, while the inner layers are used for weaving wearable fabric.

Weaver working a traditional silk loom

The art of the craft

Once the silk thread has been soaked in soapy water to remove all traces of sericin the yarn is then dyed, dried and ready for weaving on looms. In Thailand this is done using traditional wooden looms or on an industrial scale in factories. A traditional weaver can produce about 12 to 15 metres of fabric a day and handwoven Thai silk from the Isan region is among the finest and highly prized in the world, with stunningly bright colours and intricate designs that raise this craft to an art from.

Fried silkworm pupae, a popular street food in Thailand. Bon appetit!

of collaborative energy

Before proceeding to use the website please carefully ready our Terms and Policies

I accept Diwerent's Terms and Conditions and Privacy Policy